How to Reduce Operational Costs For Commercial Buildings With an HVAC Management System

HVAC systems represent the single largest energy consumer and a major operational cost center in most commercial buildings. Without efficient HVAC management, these systems drain resources continuously through wasted energy and unnecessary maintenance expenses.

Many facility managers struggle with the challenge of balancing comfortable environments while minimizing operational costs. Unoptimized HVAC leads to wasted energy, reactive maintenance, and premature equipment failure—all directly impacting your budget and bottom line.

An HVAC management system offers the precise control and insights needed to significantly reduce these costs. As a key component of effective energy management systems for commercial buildings, these technologies enable smarter decisions and automated efficiency.

This article details the concrete ways these systems cut expenses and improve building performance, providing actionable strategies for facility managers and building owners.

The Hidden Drains of Unmanaged HVAC

Excess Energy Consumption

Poor scheduling, inconsistent temperatures, and running systems when unnecessary drive up energy bills significantly. Without proper HVAC management, systems frequently operate at full capacity regardless of actual needs. Common issues include:

- Cooling or heating unoccupied spaces

- Simultaneous heating and cooling (fighting systems)

- Inefficient temperature setpoints

- Running equipment outside optimal efficiency ranges

These inefficiencies can increase energy costs by 15-30% compared to buildings utilizing effective HVAC control systems.

Reactive Maintenance Costs

Emergency repairs cost 3-5 times more than planned maintenance. When minor issues go undetected due to limited monitoring capabilities, they escalate into system failures that require immediate attention, often during peak business hours.

Reactive maintenance scenarios typically involve:

- Rush service charges from HVAC contractors

- Expedited parts delivery fees

- Business disruption costs

- Overtime labor expenses

HVAC management provides early detection of potential issues before they become emergencies.

Premature Equipment Replacement

HVAC equipment represents a substantial capital investment. Constant stress from unoptimized operation reduces equipment lifespan by up to 30%. Common causes include:

- Excessive cycling (starting/stopping)

- Running at extreme capacities

- Lack of regular maintenance

- Improper control sequences

Early replacement of major components like chillers, boilers, or air handlers can cost hundreds of thousands of dollars—costs that proper HVAC management helps defer through optimized operation.

Operational Inefficiencies

Operational Inefficiencies

The labor costs associated with manually managing HVAC systems add up quickly:

- Staff time spent making manual adjustments

- Responding to occupant complaints about temperatures

- Troubleshooting mysterious comfort issues

- Manually collecting and analyzing system performance data

What a Management System Does for Your Bottom Line

HVAC management systems translate technical capabilities into direct cost savings through several core functions. These systems form a critical part of energy management systems for commercial buildings.

Precision Control Scheduling

An HVAC control system provides granular control over zones and equipment, enabling precise scheduling based on actual building usage patterns. This capability:

- Automatically adjusts operations based on occupancy schedules

- Provides zone-level control for different building areas

- Enables holiday and special event scheduling

- Eliminates the energy waste of manually controlled systems

Buildings with precision scheduling typically see 10-15% immediate energy savings compared to traditional control methods.

Optimization Calibration

HVAC energy management systems monitor real-time conditions—temperature, humidity, CO2, occupancy—and automatically adjust system parameters for peak efficiency while maintaining comfort standards.

Advanced systems include:

- Supply air temperature reset based on demand

- Static pressure optimization

- Chilled water temperature optimization

- Fan speed adjustment based on actual needs

These optimizations can reduce HVAC energy consumption by an additional 5-20% beyond basic scheduling.

Fault Detection Diagnostics (FDD)

An advanced HVAC energy management system includes robust FDD capabilities that identify performance issues or potential failures early through continuous monitoring:

- Stuck dampers or valves

- Failing sensors

- Refrigerant leaks

- Inefficient operation patterns

By alerting facility managers before breakdowns occur, these systems reduce repair costs and prevent the domino effect of one component failure causing stress on other parts of the system.

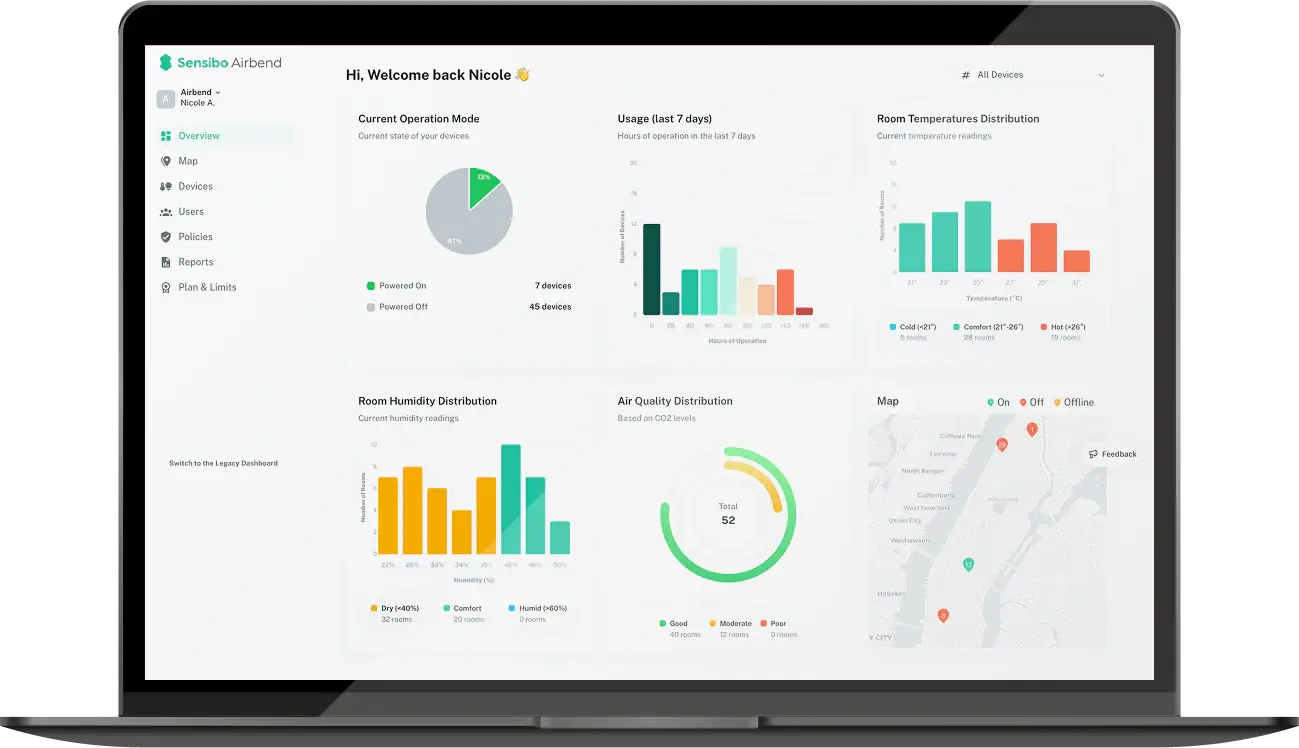

Data Collection Analysis

Effective HVAC management relies on data. These systems log historical performance, providing valuable insights into:

- Energy usage patterns across different seasons

- Equipment performance trends

- Occupancy patterns affecting system demands

- Opportunities for further optimization

This data, when integrated into broader HVAC building management systems or energy management systems in commercial buildings, enables continuous improvement and informed decision-making.

Specific Strategies the System Uses to Reduce Costs

Let's examine the practical strategies enabled by an HVAC control system that directly cut operational expenses.

Let's examine the practical strategies enabled by an HVAC control system that directly cut operational expenses.

Optimized Start/Stop

Rather than using fixed schedules, smart HVAC management calculates the ideal time to activate heating or cooling based on:

- Building thermal characteristics

- Outside weather conditions

- Required temperature at occupancy

- Historical performance data

This approach minimizes runtime while ensuring comfort when people arrive. Buildings typically achieve 5-10% energy savings through optimized start/stop algorithms alone.

Demand Control Ventilation (DCV)

Energy management systems for commercial buildings often include DCV, using CO2 sensors to modulate outside air intake based on actual occupancy. Since conditioning outside air accounts for 20-40% of HVAC energy use, this strategy:

- Reduces heating/cooling loads during partial occupancy

- Maintains air quality standards with minimum energy use

- Automatically responds to varying occupancy patterns

- Eliminates the waste of fixed ventilation rates

DCV typically reduces ventilation-related energy costs by 10-30%.

Temperature Setbacks

Automated temperature adjustments during unoccupied periods create substantial, easy energy savings:

- Wider temperature bands when spaces are empty

- Night setbacks for heating seasons

- Weekend and holiday scheduling

- Gradual recovery to avoid demand spikes

Each degree of setback typically saves 2-3% on heating/cooling costs during unoccupied hours.

Load Shedding Integration

HVAC energy management systems can participate in utility demand response programs or shed non-critical loads during peak pricing periods. This capability:

- Reduces costly demand charges

- May qualify for utility incentives

- Minimizes energy use during highest-cost periods

- Maintains comfort in critical areas while reducing overall load

Buildings with load management strategies often reduce peak demand charges by 10-20%.

Predictive Maintenance

Performance data from the HVAC management system allows maintenance to be scheduled proactively:

- Identifying performance degradation before failure

- Scheduling maintenance during low-occupancy periods

- Focusing resources on equipment showing warning signs

- Extending equipment life through timely intervention

Predictive maintenance typically reduces repair costs by 12-18% while extending equipment lifespan.

How Better HVAC Management Boosts More Than Just Savings

Beyond direct cost reductions, a robust HVAC management system contributes to overall operational efficiency and building value.

Enhanced Occupant Comfort Productivity

Stable temperatures and improved air quality reduce tenant complaints and positively impact productivity:

- Fewer hot/cold calls from occupants

- Consistent comfort across different building zones

- Better humidity control reducing mold risks

- Improved ventilation reducing sick building syndrome

Studies show productivity improvements of 1-3% in buildings with optimal thermal comfort—a significant return considering labor costs far exceed energy costs in most commercial settings.

Extended Equipment Lifespan

By optimizing system operation, HVAC management reduces stress on components:

- Fewer hard starts/stops

- Reduced runtime hours

- Operation within design parameters

- Early intervention before cascading failures

These benefits typically extend equipment life by 15-20%, delaying costly capital replacements by years.

Simplified Reporting Compliance

Automated data collection aids in sustainability reporting and energy audits:

- Tracking energy use for ENERGY STAR certification

- Documenting efficiency improvements for incentive programs

- Providing verification for green building certifications

- Simplifying compliance with energy disclosure ordinances

These capabilities save administrative time while potentially qualifying buildings for certifications that enhance market value.

Choosing Implementing Your HVAC Management System

Selecting the right smart HVAC management system requires careful consideration of your building's specific needs.

Selecting the right smart HVAC management system requires careful consideration of your building's specific needs.

Key Considerations

Look for these features when evaluating systems:

- Scalability to grow with your needs

- Integration capabilities with existing equipment

- User interface ease for staff adoption

- Vendor support and training resources

- Cybersecurity protections

- Remote access capabilities

- Data export and reporting features

The best system balances sophistication with usability for your team's technical capabilities.

Assessment is Key

Before investing in HVAC management technology, conduct a thorough assessment of:

- Current equipment capabilities and limitations

- Operational pain points and priorities

- Expected ROI for different system features

- Staff capabilities and training needs

- Budget constraints and phasing possibilities

This evaluation helps ensure the selected system addresses your most significant cost-saving opportunities.

Implementation Overview

A successful implementation typically includes these stages:

- Planning and system design

- Installation and integration with existing systems

- Testing and commissioning

- Staff training and documentation

- Performance verification

- Ongoing optimization

Proper implementation ensures maximum return on your investment in energy management systems for commercial buildings.

FAQ

What is an HVAC management system?

An HVAC management system is technology that centralizes control of heating, ventilation, and air conditioning equipment. It combines hardware and software to monitor conditions, automate adjustments, collect performance data, and optimize operation for energy efficiency and comfort. These systems range from basic programmable controllers to sophisticated platforms that integrate with broader building systems.

How do HVAC management systems save money?

HVAC management systems reduce costs through multiple mechanisms: minimizing energy consumption through precise scheduling and optimization, reducing maintenance expenses through early fault detection, extending equipment life through optimal operation, decreasing labor costs through automation, and improving space utilization through zone-level control. Most buildings see 15-30% energy savings along with significant maintenance cost reductions.

What is the difference between an HVAC control system and an HVAC management system?

An HVAC control system typically focuses on basic operation—setting temperatures, controlling equipment cycling, and maintaining setpoints. An HVAC management system includes these functions but adds advanced capabilities like analytics, fault detection, optimization algorithms, reporting tools, and often integration with other building systems. Management systems provide the intelligence layer above basic control functions.

Can these systems integrate with existing HVAC equipment?

Yes, most HVAC management systems can integrate with existing equipment through various interfaces, though certain advanced features may require equipment upgrades. Older systems might need controllers or sensors added to connect with the management platform. A good system provider will assess your current infrastructure and recommend the most cost-effective integration approach.

What kind of ROI can I expect from an HVAC management system?

Most commercial buildings see ROI within 1-3 years from implementing HVAC management systems, with energy savings of 15-30% common. Buildings with older, inefficient control systems often see faster payback. ROI improves when factoring in reduced maintenance costs, extended equipment life, and productivity benefits from improved comfort.

Are these systems only for large buildings?

No, HVAC control systems exist for buildings of all sizes. While large facilities may justify more sophisticated solutions, scalable options are available for smaller buildings with compelling ROI. Cloud-based solutions have made advanced features more accessible to smaller properties, though the specific features and complexity will vary based on building size and needs.

.jpg?height=200&name=photo_2025-01-17_21-00-09%20(1).jpg)